1-100 Micron, 10-50 Inch PP String Wound Filter Cartridge Applied For Water Treatment

RAMPA’s PP string wound filter cartridge is constructed in our 10,0000- grade clean workshop, by using FDA approved PP yarns, by our advanced computer added modeling processing system to make its quality far high above the quality for which a pre-filtration filter element need to meet.

Our PP string wound filter work with PP melt-blown and NSF approved CTO filter, it is surely an ideal filtering performance can be achieved in water treatment field.

PP String Wound Filter Cartridge Structure

Tightness of three layers progressively increasing from outside to inside design to maximize its excellent dirty holding capability. Meanwhile the wound-pattern we use extremely optimizes its geometrical space between yarns and extends the effective filtering area taking advantage of these diamond-shaped space.

PP String Wound Filter Cartridge Material

Though as other factories, we are talking about PP (PP), but there is some different. We have many grades of PP materials for customers’ selection.

Since PP string wound filter cartridges are wildly used in different industries, such as: pharmacy, food and beverage, municipal water treatment, chemical filtering solution, waste water treatment, petrochemical engineering, etc.

Some waters, or maybe other liquids, are touched by human being, some are not. Hence we classified our PP particles into different safety grades according to industrial requirement, from common grade for industries where waters are not for drinking to food grade, to medical grade, etc.

Why PP Material For Making String Wound Filter Should Be Classified?

In consideration of cost:

RAMPA has PP pellets approved by FDA which is safe in contact with food, drinks, etc. But comparing to common PP pellets, the price would be higher a lot. For places like sewage water filtration, well-filling water filtration, is it necessary to use these materials making PP string wound filter elements? We believe that the answer is negative. Using common PP pellets we can reduce much cost hence cut price for customers, from this point, PP string wound filter cartridge is a really economical filter elements.

Consideration on health:

RAMPA cares about health of human being and animals, when a customer inquire us about PP string wound filter cartridge, the first question we ask would be “where will you use the filter?” We are able to assure all our global customers that the string wound filter which would in contact with food or drinks, it must be made from first-hand, FDA-approved PP material.

PP String Wound Filter Cartridge Connection Methods Introduction.

Normally end-users get a metal bar through the inner core, and use two screw caps to fix a PP string wound filter in liquid filter housings. This is a not bad method for installing filter cartridges, but along with creative filter housing inner structure, or filter cartridges appear loose after working long time under high temperature liquid.

So as to work out these problems we occasionally got from our customers previously. We tried it from two aspects:

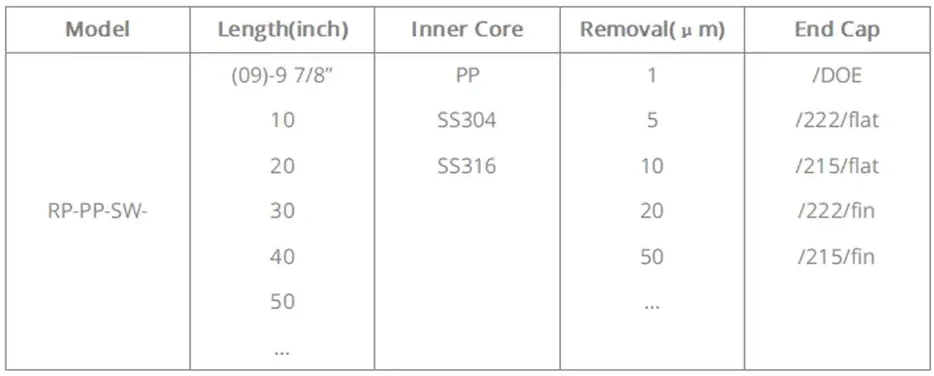

- Many types of adaptor developed, including 222, 215, Non-equal-diameter couplers, to match various connections.

- Except for the connections above, we use stainless steel 304 or 316 as inner bar to increase its compressive strength.

How Does Removal Rating Be Controlled Precisely In Production?

PP string wound filter cartridges with various sizes are all made by using a machine called Yarn Spinner. Many customers can’t understand how a factory control its removal rating.

Actually, this is a just-in-case method for all factories who make string wound filter elements. They have to try for commonly used removal ratings like 1 micron, 5 micron, 10 micron, etc. By adjusting the thickness of yarns, spinning patterns and degree of traction in spinning.

Although for many industries, accurate removal rating data is unnecessary for industrial need, and PP string wound filter is not also a absolute precision filter element, but we still insist that our PP string wound filter should enhance its filtering efficiency as possible as we can, after countless testing and tweak on filter itself and machine, now we can guarantee that filtering efficiency of RAMPA’s PP string wound filters are highly above 90% (it is just pretty good that common PP string wound filters in markets can reach 60-70%).