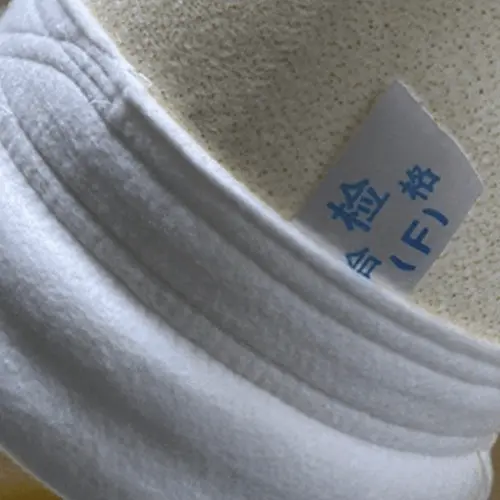

Metamax needle felt bag made under brand 3F are rigorously tested before shipment in order to extend its service life and meet harsh application environment.

3F custom filter bags include: all-purpose liquid filter bags, dust collector filter bags, and other filter bags applied in special industries.

Note: some images may be representative, please contact our Sales Engineer for detailed technique data.

Specification

| Dimension | D130-140mm |

|---|---|

| Filter Bag Type | Dust filter bag |

| Material | Metamax |

| Removal Rating | 300-1000 mesh |

| Edge | sewn |

| Working Temp. | 200 centigrade |

| Application | Dust collector |

Description

3F, a professional filtration products company, makes and offers a comprehensive selection of high-quality, China-made liquid and dust filter bags, we provide liquid filter bags, micron filter bags, dust filter bags, as well as bag filter housings, vessels and a variety of replacement parts. 3F’s dust filtration offerings include the most requested pleated bags and dust cartridges.

Weight: 500-600g/sqm.

Thickness: 1.8-2.0mm

Working Temperature: <=130 centigrade

Moment Withstand Temperature: 150 centigrade

Air Permeability: 130L/SQM./S.

Acid Resistance: average

Alkali Resistance: average

Surface Treatment: singeing, press polish or PTFE coating

Weight: 500-600g/sqm.

Thickness: 1.8-2.0mm

Working Temperature: <=130 centigrade

Moment Withstand Temperature: 150 centigrade

Acid Resistance: excellent

Alkali Resistance: good

Weight: 500g/sqm.

Thickness: 1.8mm

Working Temperature: <=130 centigrade

Moment Withstand Temperature: 150 centigrade

Acid Resistance: good

Alkali Resistance: average

Weight: 500g/sqm.

Thickness: 1.8mm

Working Temperature: <=130 centigrade

Moment Withstand Temperature: 150 centigrade

Air Permeability: 200L/SQM./S.

Acid Resistance: good

Alkali Resistance: good

Surface Treatment: singeing, press polish or PTFE coating

Weight: 500-600g/sqm.

Thickness: 1.8-2.0mm

Working Temperature: <=125 centigrade

Moment Withstand Temperature: 130 centigrade

Air Permeability: 200-300L/SQM./S.

Acid Resistance: average

Alkali Resistance: excellent

Surface Treatment: singeing, press polish or coating

Weight: 500-600g/sqm.

Thickness: 1.8-2.0mm

Working Temperature: <=200 centigrade

Moment Withstand Temperature: 210 centigrade

Acid Resistance: good

Alkali Resistance: good

Surface Treatment: singeing, press polish or coating

Weight: 750-800g/sqm.

Thickness: 1.6-2.0mm

Working Temperature: <=260 centigrade

Moment Withstand Temperature: 280 centigrade

Air Permeability: 50-120L/SQM./S.

Acid Resistance: excellent

Alkali Resistance: excellent

Surface Treatment: PTFE soaking, laminating or coating

Weight: 500-600g/sqm.

Thickness: 1.8-2.0mm

Working Temperature: <=160 centigrade

Moment Withstand Temperature: 190 centigrade

Air Permeability: 130-200L/SQM./S.

Acid Resistance: excellent

Alkali Resistance: average

Surface Treatment: PTFE soaking or coating

Weight: 500-600g/sqm.

Thickness: 1.8-2.2mm

Working Temperature: <=240 centigrade

Moment Withstand Temperature: 260 centigrade

Air Permeability: 200-300L/SQM./S.

Acid Resistance: excellent

Alkali Resistance: excellent

Surface Treatment: PTFE soaking or coating

Weight: 800-1000g/sqm.

Thickness: 2.0mm

Working Temperature: <=220 centigrade

Moment Withstand Temperature: 280 centigrade

Air Permeability: 200-300L/SQM./S.

Acid Resistance: good

Alkali Resistance: good

Surface Treatment: PTFE soaking, press polish, hot-setting

Weight: 500g/sqm.

Thickness: 1.8-2.0mm

Working Temperature: <=200 centigrade

Moment Withstand Temperature: 250 centigrade

Acid Resistance: average

Alkali Resistance: average

Surface Treatment: hot-setting, singeing, press polish or PTFE laminating

Weight: 900-1000g/sqm.

Thickness: 2.0-2.2mm

Working Temperature: <=260 centigrade

Moment Withstand Temperature: 300 centigrade

Air Permeability: 100L/SQM./S.

Acid Resistance: excellent

Alkali Resistance: excellent

Surface Treatment: PTFE membrane laminating

Weight: 900-1000g/sqm.

Thickness: 2.0-2.2mm

Working Temperature: <=280 centigrade

Moment Withstand Temperature: 300 centigrade

Acid Resistance: average

Alkali Resistance: average

Exclusive threads for dust filter bags are selected, 3-line stitching assure solid in site application.

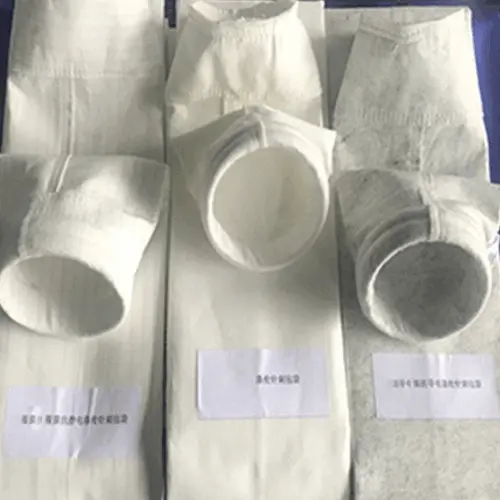

Various filter media fabrics for selection, automatic production lines to meet global market demand.

Dust filter bags are recommended according to different working conditions like temperature, gas PH value, etc

All our filter bags are customized as per customer’s demands including size, material, surface treatment types, etc.

Filter Bag Media

PP, PET, PTFE, Nylon, PMIA, NMO, ACRYLIC, PPS, P84, Glass fiber, Stainless steel screen, etc.

O-Ring Material

PP, 304, 316 etc.

MOQ

As low as to 10 pcs per size.

Filter Cloths - Dust Filter Bag

Workshop Display

Floor 1A, Nanyang Building. Yinzhou CBD, Ningbo City, 315000, P.R.China

Bldg.7 Huiju Industry Park, Yinxian Ave. Yinzhou District, Ningbo City, 315000, P.R.China

Tel: +86 574 8739 1115

Mobile Phone: +86 137 7744 5517

Email: info@umecotech.com

© 2024 UMECO TRADING (HK) CO., LIMITED – ALL RIGHTS RESERVED – ISO 9001:2015 CERTIFIED